4 2 generally resistance to compression is the measure of the greatest strength of a monolithic advanced ceramic.

Ceramics have greatest resistance to compression.

4 2 generally resistance to compression is the measure of the greatest strength of a monolithic advanced ceramic.

Ideally ceramics should be compressively stressed in use although engineering applications may frequently introduce tensile stresses in the component.

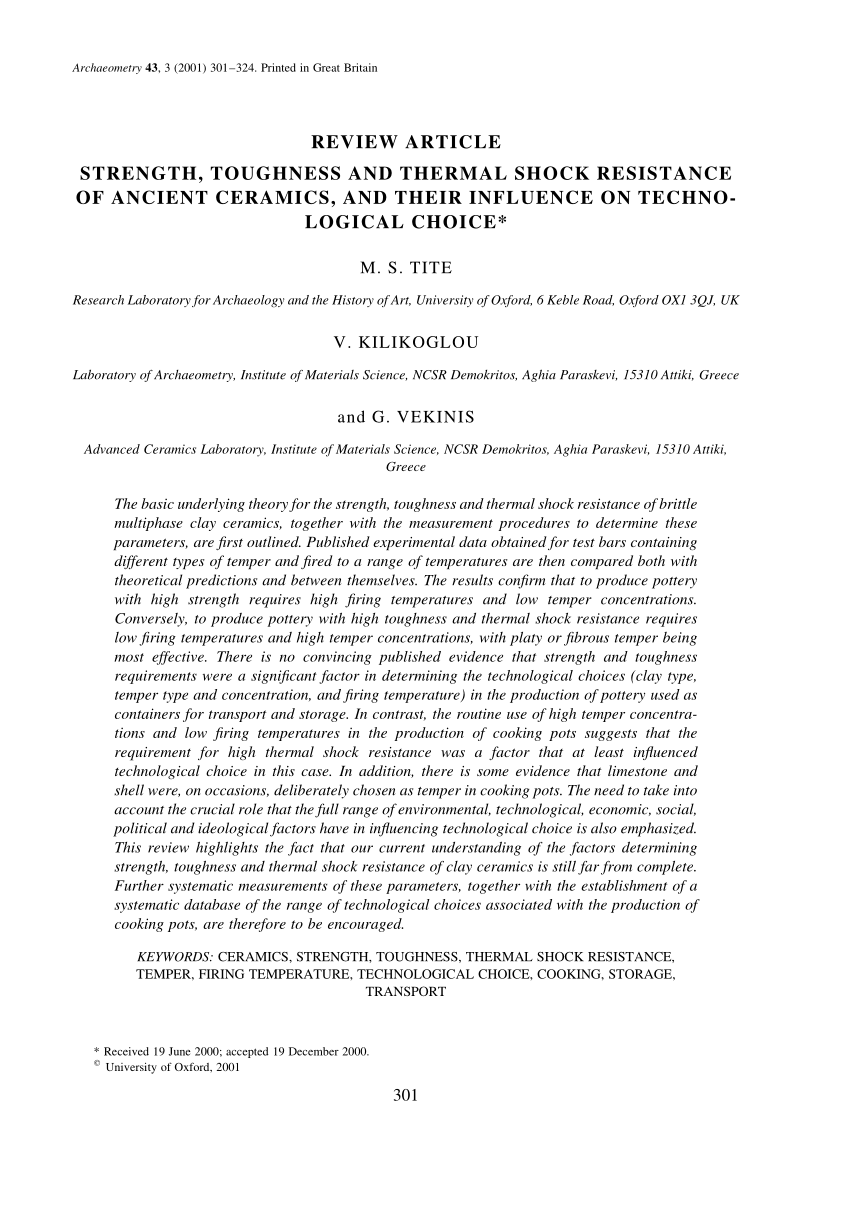

Introduction structural ceramics have excellent mechanical properties such as high strength low specific weight and corrosion resistance even at high temperature.

Their strength depends on the number and type of defects that are present.

Ideally ceramics should be compressively stressed in use although engineering applications may frequently introduce tensile stresses in the component.

In addition aluminas are susceptible to corrosion from strong acids steam and sodium.

Ceramics are very sensitive to cracks impurities and porosity and thus generally have low toughness.

Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa.

Generally a ceramic with more defects is weaker.

Glass ceramics 1 3 glasses 1 material k mpa m1 2 ic ceramics are defect limited.

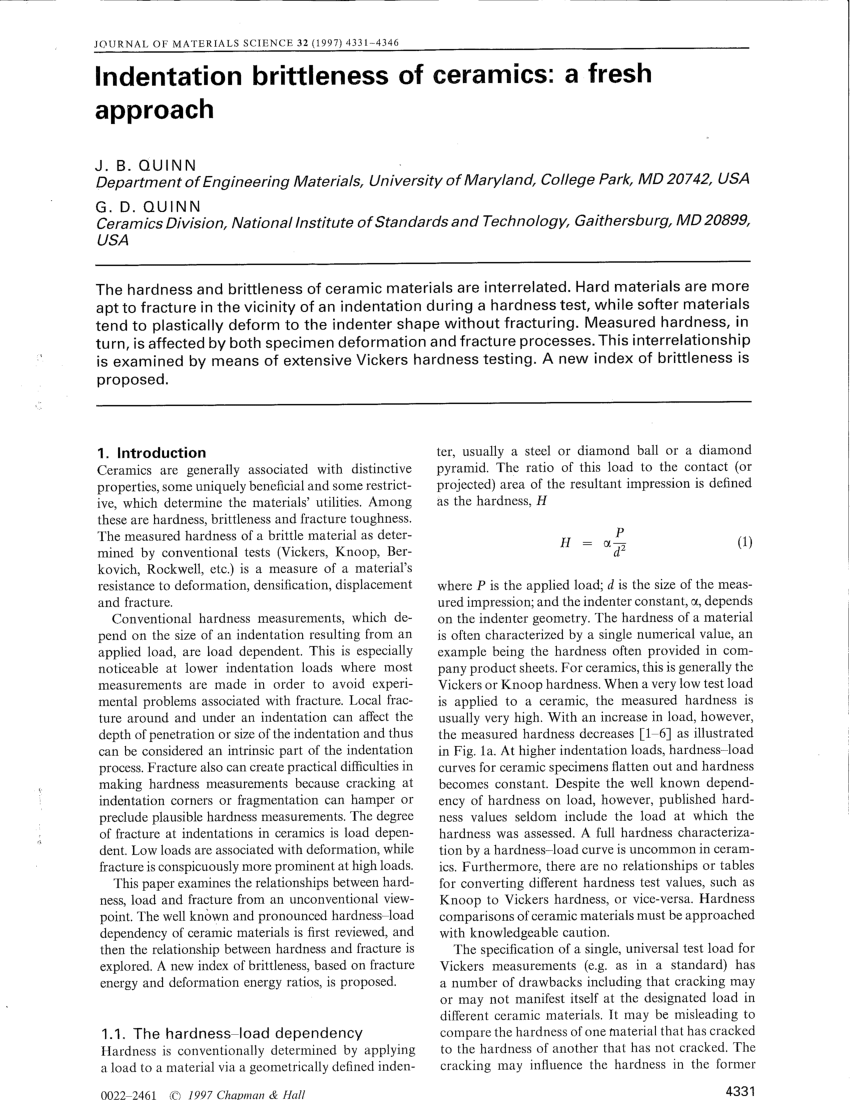

There is a need to know accurately the strength of brittle materials in compression both to distinguish between competing statistical micromechanical theories of strength and to provide data necessary for engineering designs for the optimum use of these materials as load bearing elements.

Ceramics thus were considered an ideal material for heat engines because they would make it possible to raise the combustion temperature and would improve the thermal efficiency.

For a metal the compressive strength is near that of the tensile strength while for a ceramic the compressive strength may be 10 times the tensile strength.

In compression however the flaws in the material do not cause stress concentrations or crack propagation as they do in tension.

Another way at looking at resistance to failure for ceramic materials is to examine the energy required to drive cracks through the system.